Karl Lagerfeld Paternoster Lift

[UK]2024 Client

Karl Lagerfeld

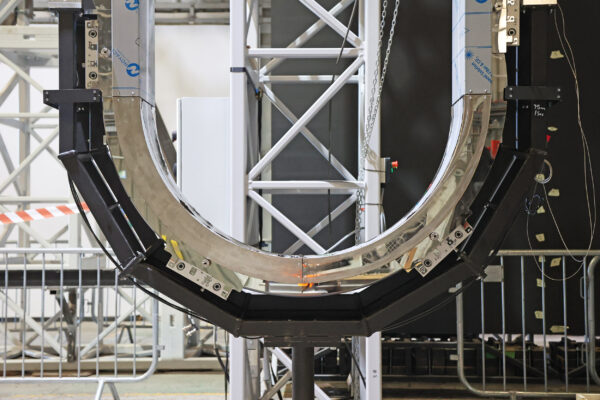

The refurbishment of Karl Lagerfeld’s flagship store saw Stage One design, engineer and manufacture a paternoster lift as part of its new Future Legacy concept.

Grand in scale. Complex in engineering. Yet it was to fit in only a small space. Our team rose to the challenge.

The paternoster lift circulates a display of accessories between the two floors of the store. To be congruent with the minimalistic aesthetic, it needed to be sleek, quiet, straightforward to operate and safe for a live retail environment.

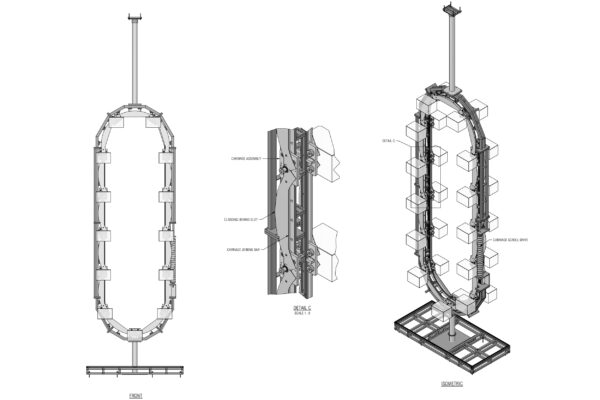

The initial step was to design the structure and then assess the mechanical requirements. Our engineers first looked at various drive arrangements, there were many options that could work, we needed to find the one that would work best. Considering our requirements, in combination with long lead times on some items, we selected and procured a very high strength linear rail system that would deliver the bend radius required for the loop section.

The system was designed around these components, involving an unusual structural assessment:

- Consideration of the stiffness and deflection of the tracks, reducing the section sizes of the structural frame and therefore overall weight, which was limited by the allowable floor loading

- The requirement for minimal structural connections to the existing building; firstly, to minimise vertical noise transferral to prevent disturbance to the offices above, whilst preventing any structural interference to the London Underground transport network located below

- To identify and engineer out any potential safety hazards when in a public environment, whilst maintaining a high-end aesthetic.

The design intent was first reviewed with, and agreed, by the client and so we moved into test build in our workshops in York. We built the steel structure and tested the mechanics. The final stage was the steel cladding.

The test build was stripped, loaded and delivered to site – not an easy feat on one of Central London’s busiest streets. Arriving on site, the conditions were not as expected and required a rethink of our planned lifting arrangement.

With the structure located within the centre of a staircase, space was limited, and plant equipment could not be used. The structure was installed manually, by two crew, two hoists and a lifting frame, whilst working at height was carried out with the support of a scaffold tower.

Installation and commissioning were completed in two weeks in preparation for the store opening.

2024 Client

Karl Lagerfeld